The Ultimate Guide to Advanced Foam Control Techniques and Solutions

The Ultimate Guide to Advanced Foam Control Techniques and Solutions

Blog Article

The Function of Foam Control in Enhancing Item Top Quality and Efficiency

Foam control is an often-overlooked yet important part in the quest of item top quality and operational effectiveness across diverse industries. This discussion will certainly check out the complex impact of foam on both item honesty and manufacturing procedures, raising vital concerns concerning the techniques that can be used to optimize foam control.

Recognizing Foam Development

Foam formation is a complicated sensation that can substantially impact product quality and functional performance throughout numerous sectors. Recognizing these variables is crucial for taking care of foam efficiently.

The fluid's viscosity and surface area tension play pivotal duties in foam security. Surfactants, for example, can decrease surface stress, promoting bubble development yet likewise boosting foam stability, which can be troublesome in particular applications. Mechanical frustration, temperature level changes, and the visibility of contaminations can exacerbate foam generation, making it necessary to check these facets during production procedures.

Industries such as food and drink, pharmaceuticals, and chemical production must be especially alert concerning foam control. By realizing the hidden devices of foam formation, organizations can carry out targeted techniques to reduce its effects, thus preserving operational performance and guaranteeing constant product efficiency.

Influence On Item Top Quality

The presence of foam can dramatically jeopardize item quality across different markets. In producing procedures such as food and drink, pharmaceuticals, and cosmetics, extreme foam can result in irregular product solutions. As an example, in food production, foam may trap air, impacting structure and flavor, which can eventually alter customer assumption and contentment.

Additionally, foam can impede the uniformity of coatings and paints, leading to problems like bubbles and unequal coatings. In pharmaceutical applications, foam can disrupt the precise application of liquid drugs, possibly influencing therapeutic efficacy and client safety and security. These quality problems not only diminish completion item's allure yet can also cause expensive recalls and damage to brand track record.

Furthermore, the visibility of foam can complicate quality assurance procedures, making it hard to accomplish constant results and exact dimensions. Reliable foam control not only minimizes these threats however likewise improves overall item quality by guaranteeing that solutions meet rigid industry criteria. By buying foam control techniques, firms can guard their products, enhance client contentment, and preserve an one-upmanship in the industry.

Operational Challenges From Foam

Effective operations in different industries can be significantly interrupted by the existence of foam, which postures multiple obstacles throughout manufacturing processes. Foam can prevent blending and response times, restraining the effectiveness of chemical processes. In industries such as food and drink, foam development can cause imprecise fill levels, causing item waste and disparities in packaging.

In atmospheres where health is vital, such as drugs and food processing, foam can make complex cleansing methods, producing surprise reservoirs for contaminants. This not only raises high quality concerns however also can bring about conformity problems with regulatory criteria.

Moreover, the emotional influence on operators can not be overlooked; excessive foam can develop a disorderly workplace, causing lowered morale and efficiency. In recap, attending to the functional obstacles posed by foam is important to keeping efficiency and product quality in various industries.

Strategies for Effective Foam Control

Just how can markets efficiently reduce the obstacles posed by foam? Effective foam control strategies are necessary for improving product high quality and functional performance.

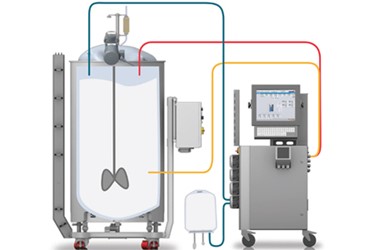

Along with chemical services, process optimization plays an essential function in foam management. Industries can assess and readjust specifications such as blending speed, temperature, and pressure to reduce foam generation. Executing equipment modifications, like mounting foam-breaking tools or adjusting tank layout, can additionally help decrease foam levels.

Routine tracking and analysis of foam habits within manufacturing processes are likewise important. Utilizing innovative sensors and analytics can offer real-time information, enabling for timely treatments and adjustments. Staff training is just as essential; guaranteeing that employees are experienced concerning foam dynamics and control techniques can result in proactive foam monitoring.

Study and Industry Applications

While many industries deal with unique obstacles associated to foam control, study disclose that customized strategies can significantly enhance both product high quality and functional effectiveness. In the pharmaceutical sector, as an example, a leading supplier applied a custom foam control strategy that minimized foam formation throughout fermentation procedures. This technology not only boosted yield by 15% however likewise decreased contamination threats, guaranteeing higher item stability.

In a similar way, in the food and beverage industry, a significant dairy products producer faced too much foam during pasteurization - Foam Control. By presenting YOURURL.com a specialized antifoam representative, they lowered processing time by 20%, which directly equated to enhanced throughput and decreased power consumption. The application of foam control determines ensured regular product texture and preference, strengthening brand name loyalty

In the chemical production market, an see post instance study highlighted the successful application of foam control in wastewater therapy procedures. The application of a real-time monitoring system enabled operators to change antifoam dose dynamically, bring about a 30% reduction in chemical use and improved effluent quality.

These study show the diverse applications of foam control throughout industries, emphasizing its vital role in enhancing item high quality and operational performance.

Final Thought

In verdict, reliable foam control is important to improving product top quality and operational effectiveness throughout different industries. By addressing foam development, services can alleviate the adverse influence on solutions, appearance, and application precision. Implementing targeted foam administration strategies not only lowers handling hold-ups and waste however likewise reinforces devices integrity. Eventually, prioritizing foam control contributes to boosted performance, securing brand name reputation, and boosting consumer satisfaction, highlighting its value in high quality assurance within producing processes.

Foam control is an often-overlooked yet important element in the quest of item high quality and operational effectiveness across varied sectors. Staff training is just as important; ensuring that workers are knowledgeable regarding foam dynamics and control visit the site methods can lead to aggressive foam administration.

While several industries encounter unique difficulties related to foam control, instance researches reveal that tailored strategies can considerably improve both product high quality and operational effectiveness (Foam Control). In the pharmaceutical field, for circumstances, a leading maker executed a custom foam control strategy that decreased foam development throughout fermentation processes.In final thought, reliable foam control is important to enhancing item high quality and operational performance across different sectors

Report this page